Product Description:

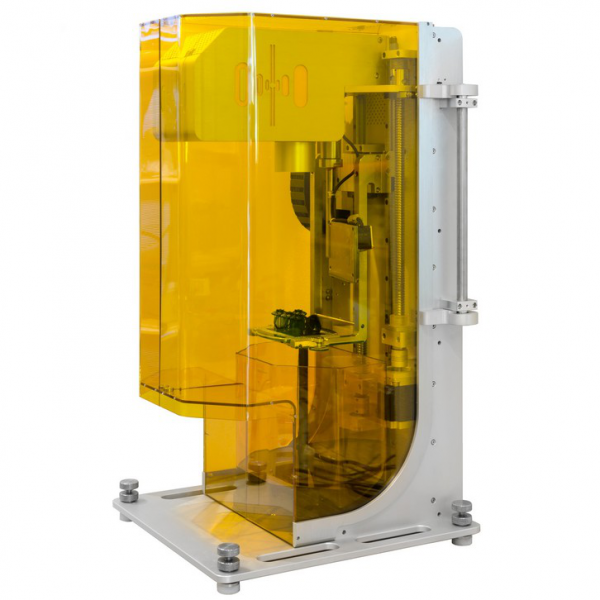

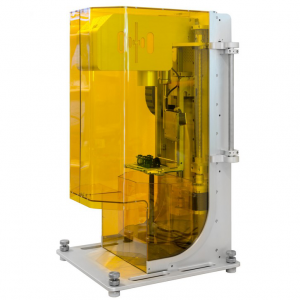

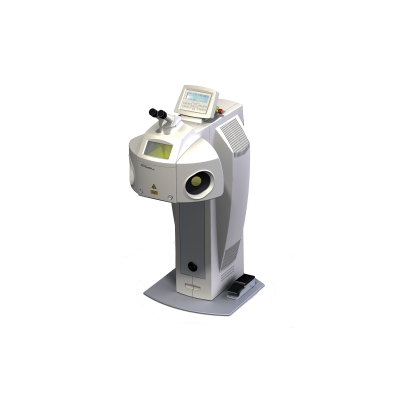

Octavelight is an indispensable assistant for model makers not only in the jewelry industry but also in dentistry and construction. This machine follows the most unique design technology to date with a platform located underneath. This...

Product Description:

Octavelight is an indispensable assistant for model makers not only in the jewelry industry but also in dentistry and construction. This machine follows the most unique design technology to date with a platform located underneath. This technology has made Octavelight well-known not only among all professionals in the jewelry market from north to south but also throughout the vast Indochina region. Achieving this recognition is thanks to the economic benefits that the Octavelight machine provides to customers.

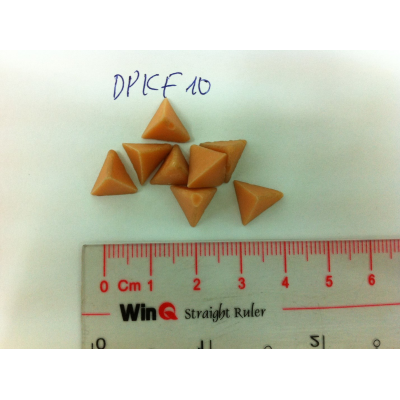

The Octavelight 50 Micro is designed for customers who have a limited sample output but require a high-quality, smooth surface. The Octavelight 50 Micro is particularly suitable for customers making high-quality jewelry and luxury items.

II. Applications

- Creates real products based on ideas from CAD/CAM design files.

- Produces samples for objects with multiple holes or hollow sections that cannot be made by hand.

- In single-piece production: 3D printing can reduce costs by up to 60%.

III. Areas of Application

- Creating samples in the jewelry industry.

- Hearing aids.

- Creating samples in dentistry.

- Creating models in the fine arts.

- Fabricating medical models: replacement bone implants and surgical assistance tools.

- Archaeology: recreating the shape of products and finally using colors to make objects resemble the original samples.

IV. Outstanding Advantages

- The machine has a large platform size.

- Excellent ability to print delicate and thin samples.

- The resin tray remains unconsumed throughout the machine's usage.

- No need to remove the platform when removing samples.

V. Specifications

| Made in | China |

| Machine Dimensions: (mm) | 580 x 410 x 820 |

| Power Supply: (V) | 220 |

| Weight: (kg) | 600 |

| Machine Type | Ocatve Light

R1 70µm | Octave Light

R1 50µm | Octave Light

R1 40µm | Octave Light

R1 30µm |

| Platform Dimensions (D x R x C) | 75.6 x 134.4 x 204 | 54 x 96 x 204 | 43.2 x 76.8 x 155 | 32.4 x 57.6 x 120 |

Resolution in Plane

X, Y: (µm/pixel) | 70 x 70 | 50 x 50 | 40 x 40 | 30 x 30 |

| Z-axis Resolution: (µm) | 5 |

| Layer Printing Capability | From 25 µm to 125 µm per layer

(Common: 25 µm per layer for jewelry printing, 50 µm per layer for dental applications, 100 µm per layer for high-speed prototype printing) |

| Light Source | UV LED: 405 nm wavelength |

| Optical Motor | UV lamp optical motor with high-precision DLP printing technology, suitable for industrial production, with a resolution of 1920 x 1080 pixels. |

| Laser Measurement Sensor | Resolution of 3 µm, capable of accurately measuring the position of the surface of the transparent liquid resin layer. Therefore, the R1 series is fully compatible with various types of transparent liquid 3D printing resins. |

| Printing Mechanism | Top-down printing |

| Sample Printing Speed | Up to 8 mm per hour when printing at 25 µm/layer

Up to 16 mm per hour when printing at 50 µm/layer

Up to 32 mm per hour when printing at 100 µm/layer

Actual printing time depends on the printing parameters set by the operator. |